![[Translate to Englisch:] EXAKT Trenn- & Schleifsysteme](/fileadmin/_processed_/9/2/csm_Labor_TDT_300_1280x384_Header_TDT-min_5d43c74473.png)

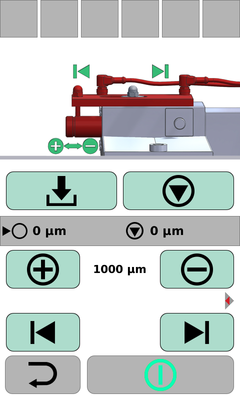

Contact Line (CL) vs. Contact Point (CP) processing

Contact Line (CL)

We named the usual cutting technology and procedure for all band saws Contact Line (CL). During the cutting process the contact between cutting band and sample is line-like. This simple method is sufficient for several applications. However, in comparison to the Contact Point (CP) method, this method generates more friction due to the larger contact area between the cutting band and the sample. Higher feed forces are required for the cutting process, which results in higher thermal and mechanical stress applied to the sample. The consequences can be lower surface quality and even structural damage to the sample. Furthermore, the cutting band will wear more quickly.

The EXAKT 300/310 CL offers a precision parallel guide with a variety of sample holders: however, solely with manual sample positioning.

Contact Point (CP)

The cutting technology named Contact Point (CP) by us only makes a point-like contact between cutting band and sample. This is achieved by an especially designed, servo driven clamping fixture which is oscillating the sample in a rotary movement. Oscillating speed as well as the angle can be adjusted.

The EXAKT 300/310 CP offers precise automatic sample positioning using the machine’s operating unit. The unit allows for positioning in 5µm steps while showing target and current values in the display.

This technology guarantees higher cutting speed, a superior quality of the cut surface and less wear of the cutting band.

![[Translate to Englisch:] CP vs CL Cutting Technology](/fileadmin/_processed_/9/2/csm_CLCP_Animation_3f8a3c1944.gif)