![[Translate to Englisch:] EXAKT Trenn- & Schleifsysteme](/fileadmin/_processed_/9/2/csm_Labor_TDT_300_1280x384_Header_TDT-min_ca004417ab.png)

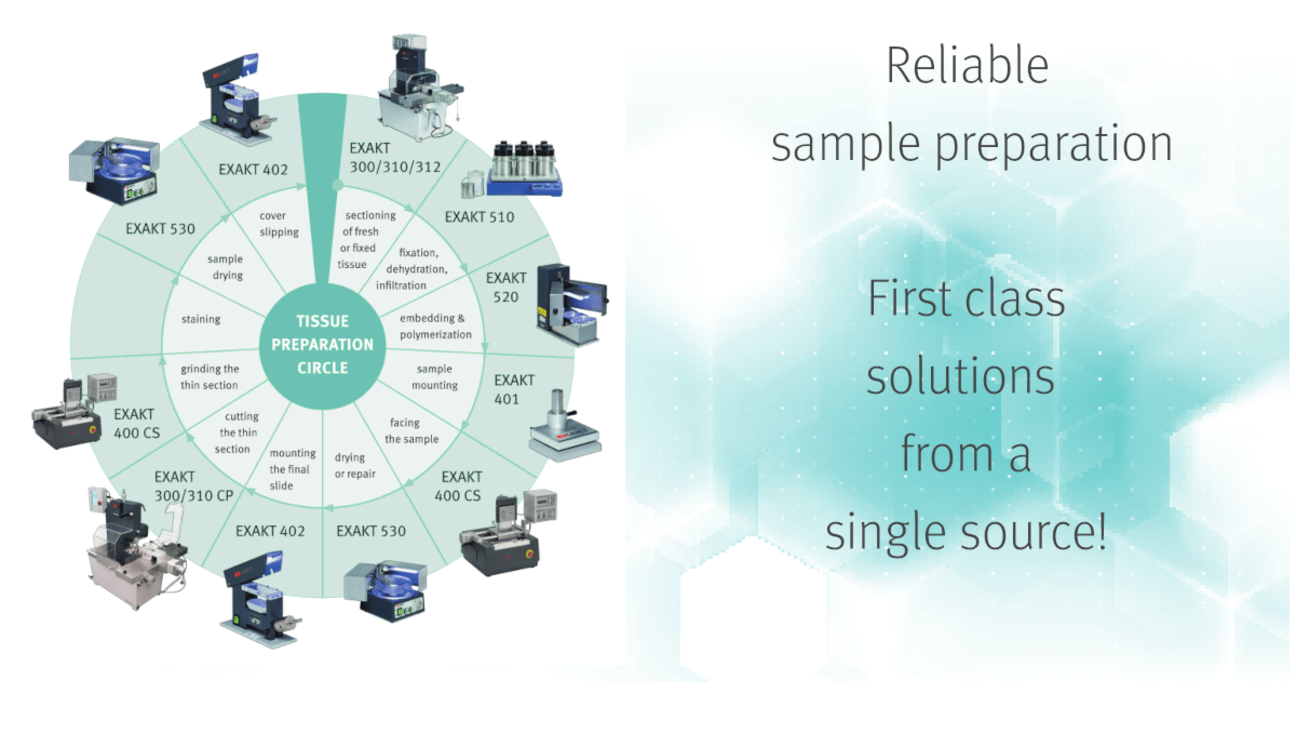

EXAKT Cutting, Grinding & Thin Section Technology

The EXAKT thin section cutting technology is a combined system for targeted cutting and treatment of highly sensitive materials.

Our technology offers precise cutting and sectioning for a wide range of applications: From medicine and implantology, industry, ceramics and metallic materials, to sensitive hard/soft combinations in cancer research or composites in R&D.

Our clients achieve material thicknesses down to 100 µm using the EXAKT thin section cutting technology - without damaging the composition,surface, or structure of the material.

Using a reduced energy input prevents deformations,crushing or stresses to the material during processing. The sample information content always remains intact. At the same time the risk of injury is minimal for operators.

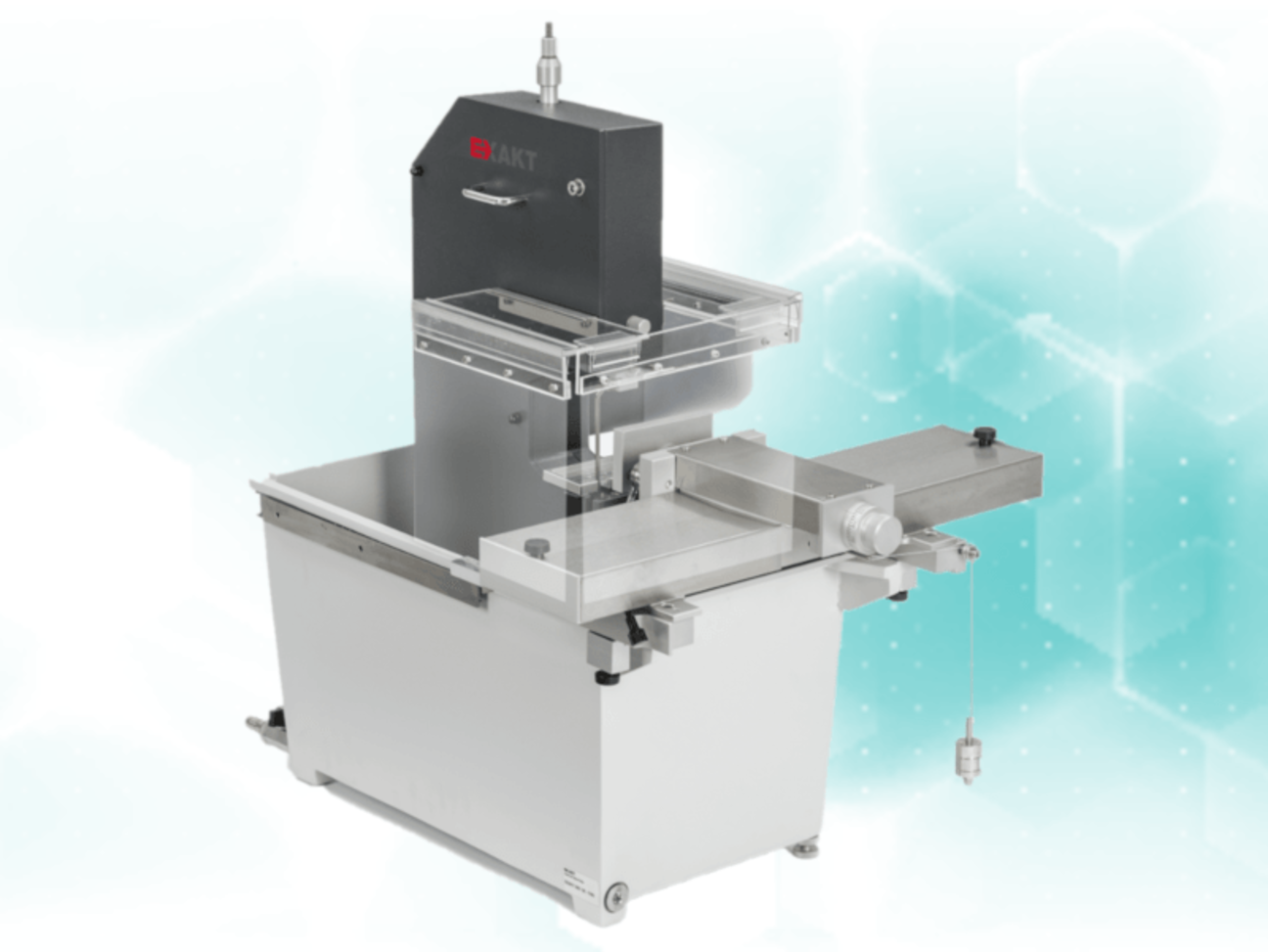

Diamond Band Saws 300, 310, 311

300 CL

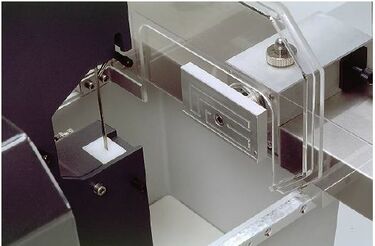

- Precise coplanar feed

- precise gravimetric setting of feed force

- µ-precise sample positioning for very thin cuts

- Minimal cutting loss

- Cutting bands: high-quality, long lasting, and available in a variety of different grits

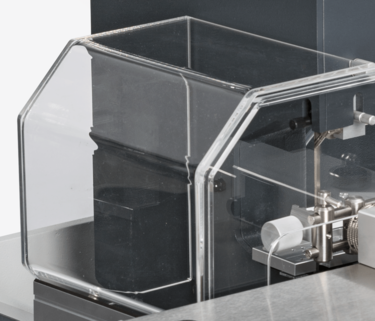

- Integrated water cooling system

300 CP

- Precise coplanar feed

- Oscillation of the sample (CP mode)

- precise gravimetric setting of feed force

- µ-precise sample positioning for very thin cuts

- Minimal cutting loss

- Cutting bands: high-quality, long lasting, and available in a variety of grits

- Integrated water cooling system

- Compact size; ideal for laboratory use

310 CP

- variety of sample intakes

- ideal to process larger samples (double size) than 300 CL /CP

- Precise coplanar feed

- Oscillation of the sample (CP mode)

- µ-precise sample positioning for very thin cuts

- Minimal cutting loss

- Cutting bands: high-quality, long lasting, and available in a variety of grits

- More powerful motor compared to the 300 CL/CP

Diamond Band Saws 302 & 312

The pathology saw EXAKT 312 and the laboratory saw EXAKT 302 were specifically developed to meet the requirements in pathology and anatomy labs and departments. Due to the excellent surface quality of the cutting surface, an initial assessment of the section can be carried out without further processing. The high cutting quality also applies to bones with implants. Using a diamond cutting band allows for thin cuts by hand and without any risk of cutting to the operator. The straightforward and application-oriented design ensures easy cleaning and disinfection after use.

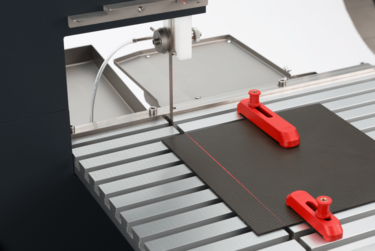

302

- Diamond Band Saw for laboratories

- Cutting bands can be changed without any tools

- Made from stainless steel

- Coplanar rip fence intergrated in working table

- LASER guided cutting

- Water cooling

Grinding system

Create μ-accurate and reproducible plane-parallel thin sections with the EXAKT 400 CS grinder. Our precise measuring technology allows you to accurately set the required material removal. The grinding and polishing processes are achieved with an accuracy of less than 5 μm depending on the selected type and fineness of the sandpaper. Follow the EXAKT sample preparation system to determine the adhesive layer thickness of the embedded samples fixed to slides. In combination with the EXAKT 400CS grinder, this process allows the safe production of thin sections down to 10 μm thickness.

Micro Grinder 400 CS

Coplanar tolerance - precise down to the micron

Vacuum mounting for different sample slide sizes

Highly precise measuring sensor for precise setting of material removal in steps down to the μ

Gentle and controlled removal through gravimetric setting of grinding force

Homogenous grind thanks to continuously adjustable oscillation of the sample in combination with grinding disk speed

Integrated water rinsing in vacuum head

Variety of abrasive and polishing papers (backing material and grit), suitable for your application

Sample Preparation

EXAKT 401

![[Translate to Englisch:] EXAKT 401 Vakuumklebepresse](/fileadmin/_processed_/b/8/csm_EXAKT_401_1000x807-min_58d05eeb5f.png)

Vacuum Adhesive Press

- Precise & coplanar

- Easy handling

for precise adhesion - Vacuum unit

for sample slides

Exakt 402

![[Translate to Englisch:] EXAKT 402 Präzisionsklebepresse](/fileadmin/_processed_/b/1/csm_EXAKT_402_1000x807-min_f419819177.png)

Precision Adhesive Press

- Bubble-free adhesion via plexiglas block

- Vacuum unit

for sample slides - Adjustable contact pressure

- Light polymerisation function

EXAKT 510

![[Translate to Englisch:] Exakt 510 Entwässerungs- & Infiltrationsgerät](/fileadmin/_processed_/3/4/csm_EXAKT_510_1000x807-min_aaf5278d47.png)

Dehydration and Infiltration Device

- Optimised for the low sample volume in research

- Fast penetration through agitation

- 6 parallel steps in a single ascending dilution series

- Vacuum attachment for perfect infiltration

EXAKT 520

![[Translate to Englisch:] EXAKT 520 Polymerisationsgerät](/fileadmin/_processed_/0/2/csm_EXAKT_520_1000x881-min_913ea46da0.png)

Light Polymerization Device

- Reproducible polymerization process

- Timers for two different intensities

- Cooling unit for samples

- Embedding molds of various sizes

- Embedding with Technovit 7200

EXAKT 530

![[Translate to Englisch:] EXAKT 530 Blocktrocknungs- & Nachinfiltration](/fileadmin/_processed_/6/d/csm_EXAKT_530_1000x807-min_b636b024fc.png)

Blockdrying and Post Infiltration Device

- Repair of cracks, blisters, artefacts

- Dehydration under vaccum heating plate at 40°C

- Time-controlled light polymerisation