![[Translate to Englisch:] Walzen Dreiwalzwerk Close-Up](/fileadmin/_processed_/2/b/csm_Abnehmer__1_von_1__05cc39c1c7.jpg)

EXAKT Three Roll Mills - precision in perfection

Targeted dispersion, homogenisation & moistening.

Welcome to the most versatile dispersion systems on the market.

No matter if you are looking for a solution for the development and production of pastes, functional materials, or any other application in wet milling, refining or mixing processes - EXAKT Three Roll Mills offer reproducible precision down to the micron and sub-micron range.

- Controlled and reproducible energy input

- Conservation of primary particle characteristics

- Defined and reproducible particle separation

- Homogeneous and very narrow particle distribution

- Processing of viscous and highly viscous pastes

- Process data analysis in real-Time (E-line)

G-LINE

powerful, precise and versatile

Our new model of the EXAKT G-LINE was designed for a versatile use in laboratories, comes equipped with a powerful drive, and the highest precision.

From industrial research to cosmetics production, the G-Line disperses a wide variety of substances, including highly viscous, functional materials. It guarantees excellent, homogeneous, and reproducible product fineness.

The user-friendly operation, compact design, and the great cost-performance ratio make the G-Line the perfect system for advanced laboratory applications.

the new standard for laboratory applications

- More powerful drive than competitive models for versatile applications

- Precise, reproducible dispersion of highly viscous materials

- User-friendly touchpad to set speed

- Precise one-hand adjustment of gap width

- Up to 5 l/h throughput* with a gap width of ten μm

- High-quality roller surfaces (chrome or aluminium oxide)

- Self-adjusting scraper system

- Prevents dry running

*theoretical throughput with low viscosity and max. power

The EXAKT 50 PLUS replaces all former EXAKT 50I and all EXAKT 50 Classic models.

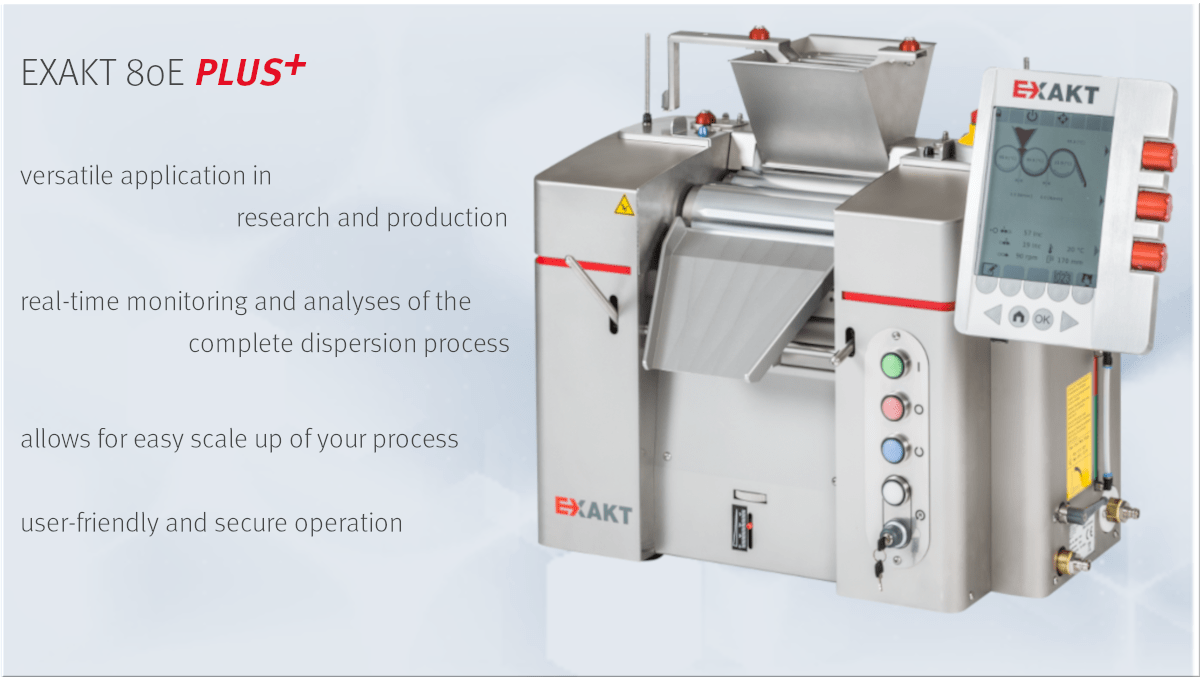

E-LINE

reliable process control

Our E-Line Three Roll Mills are equipped with a unique electronic control concept for perfect parameter regulation throughout the dispersion process.

The electronic adjustment of roller gaps in 1 μm steps and the force measurement in the roller gap offer unique dispersion and analysis functions. All relevant process parameters are displayed in real time. Using the the E-Line's optional DataLog function you can save and document, export and evaluate the respective dispersion data.

All this provides users in R&D - and in production alike - maximum control and additional quality control across a variety of applications.

80E PLUS

designed for research & development

- Electronic gap setting in 1-µ steps

- One-pass calibration - automatic adjustment of roller parallelism

- Electronic display of dispersing process in real-time

- Gap mode: roller gaps from 5 µm to 180 µm

- Force Mode: adjustable line pressing to 26 N/mm (determined by working width)

- Processing of less than 10 ml

- Throughput of up to 18l/h at 10 µm gap width

- Roller material: ceramics (Al2O3 or SiC), steel (chrome plated)

120EH-450 e-con

our production solution

- Particle fineness of less than 1 micron

- Individually select gap or force mode for each gap

- Set gaps and parallelism automatically

- Monitor and set process parameters easily

- Record process parameters via DataLog

- 27.5 l/4 throughout with gap width at 5 micron

- Roller material: ceramics (Al2O3 oder SiC) or steel (chrome plated)

- Control roller temperature for ideal process control

- Safety: overload protection, cleaning and reverse modes

S-LINE

high-performance drive for controlled dispersion of high viscosity materials

EXAKT S-Line Three Roll Mills offer the most precision and reproducibility with market leading gap settings down to 5 μm.

Despite its compact, space-saving design, a very powerful drive system allows processing of very high-viscosity materials. Depending on the respective rheological properties pastes with 5 million mPas or more can be processed, made possible by our standard roller temperature control system.

Operation is easy using the colour display to monitor speed, temperature, various production timers and power consumption. It doesn't get any more user-friendly!

80S PLUS

maximum fineness guaranteed

![[Translate to Englisch:] Dreiwalzwerk 80S PLUS](/fileadmin/_processed_/a/b/csm_DWW_80SPLUS_800x600_min_a4ceeb9f09.png)

![[Translate to Englisch:] Dreiwalzwerk 80S PLUS](/fileadmin/_processed_/6/7/csm_80E_PLUS_Temperierung-min_7c406b9f7c.png)

![[Translate to Englisch:] Dreiwalzwerk 80S PLUS](/fileadmin/_processed_/9/e/csm_WP_HS_Bedienung-min_34fe320a80.jpg)

![[Translate to Englisch:] Dreiwalzwerk 80S PLUS](/fileadmin/_processed_/1/5/csm_WB_HS_Sicherheit_und_Arbeitsbreite-min_acc56e8ae7.png)

![[Translate to Englisch:] Dreiwalzwerk 80S PLUS](/fileadmin/_processed_/0/2/csm_WB_Sicherheit_Abdeckhaube-min_3d45e85111.png)

![[Translate to Englisch:] Dreiwalzwerk 80S PLUS](/fileadmin/_processed_/b/3/csm_WB_HS_Oberflaeche-min_8aab77f2ae.png)

- Colour display

- Roller gap from 5 µm to approx. 230 µm

- Processing of less than 10 ml

- Throughput up to 18 l/h at 10 µm gap setting

- Roller material: ceramics (Al2O3 or SiC) or steel (chrome)

- Roller temperature control

- Stainless steel casing

- Particularly safe cleaning process

120S PLUS

reliable production

![[Translate to Englisch:] EXAKT 120 S PLUS](/fileadmin/Bilder/2022_02_Dreiwalzwerke/DWW_120SPLUS_800x600_min.png)

- Colour display

- Roller gap from 5 µm to approx. 220 µm

- Throughput up to 27 l/h at 10 µm roller gap

- Roller material: ceramics (Al2O3) or hardened chrome

- Temperature controlled rollers

- Stainless steel casing

- Particularly safe cleaning process