![[Translate to Englisch:] Header Trenn-Dünnschliff Branchen Labor](/fileadmin/_processed_/8/2/csm_Labor_TDT_300_1280x384_Header-min_194071afed.png)

First class solutions for efficient sample cutting

New materials and composites, complex manufacturing processes, and constantly increasing quality and safety requirements require extensive and detailed knowledge of the materials used, manufacturing processes and their complex nteractions. Use the precision and performance of our cutting and grinding devices to obtain immediate assessments of complex components and their structures, often without having to carry out further grinding and polishing steps.

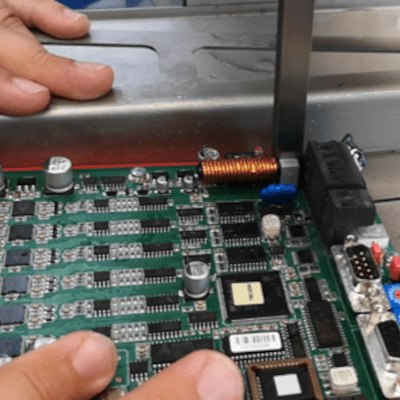

precise cut through a circuit board

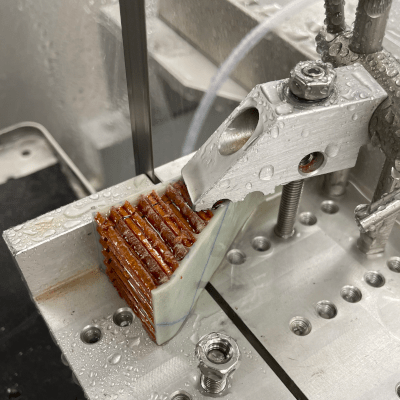

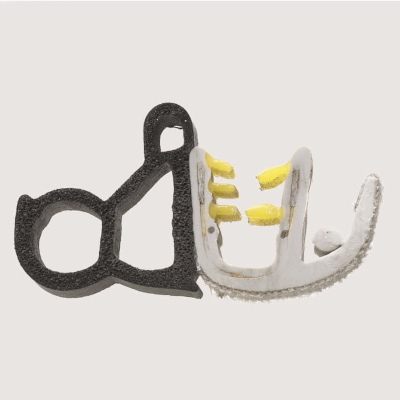

cutting of complex components

cut through a smartphone

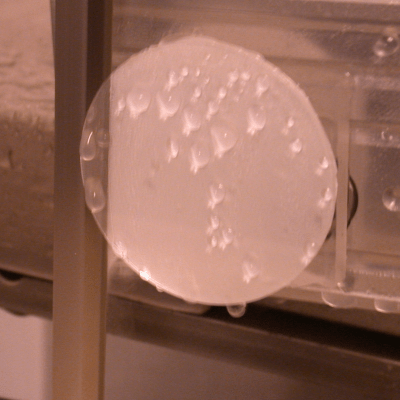

sapphire waver: separating the second hardest mineral after the diamond - not a problem for EXAKT.

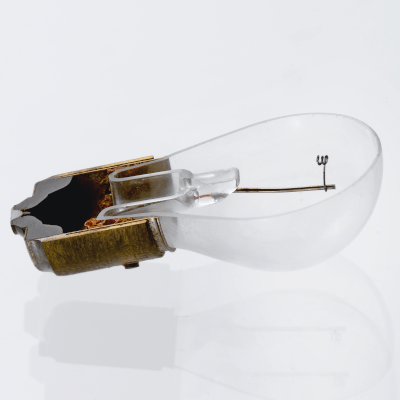

glass, metal, ceramics: separate composites without embedding - surprisingly easy.

precisely separate a wide variety of metals & metal composites (here: hardened steel with boron nitride cutting band).

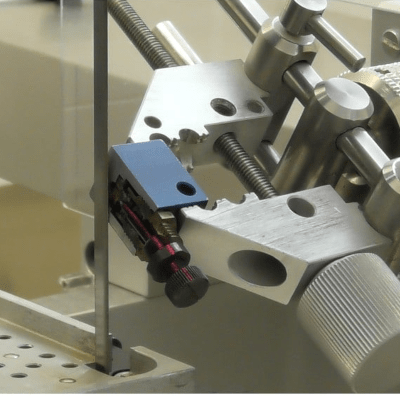

EXAKT for industrial surface cuts and cross-sectioning

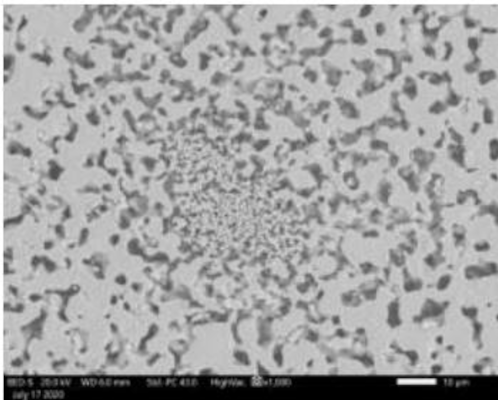

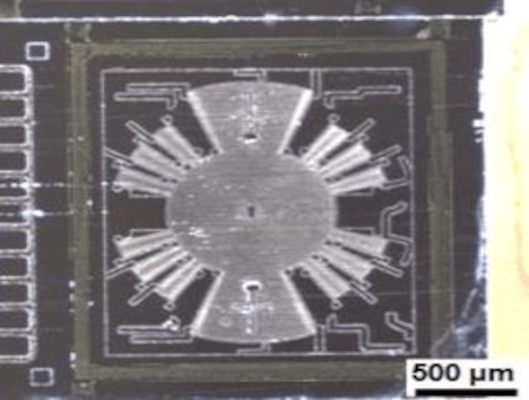

"For the quality assessment of electronic assemblies and components, mainly metallographic cross-sections are made in order to be able to reliably show details in the micrometre range. However, these cross-sections always show only a partial area of the joining zone of the actual connection. Of interest for the analysis are, for example, material composition, microstructure, distribution of phase constituents, as well as inhomogeneities such as blowholes, cavities and cracks. However, it is difficult to prepare larger areas of joining zones with layer thicknesses of a few micrometres in a plane-parallel manner. This problem can be solved with the EXAKT Micro Grinder 400CS."

Quote from Fraunhofer-Institut für Siliziumtechnologie ISIT (translated from German)

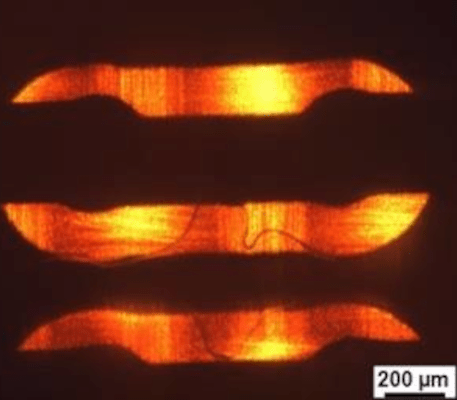

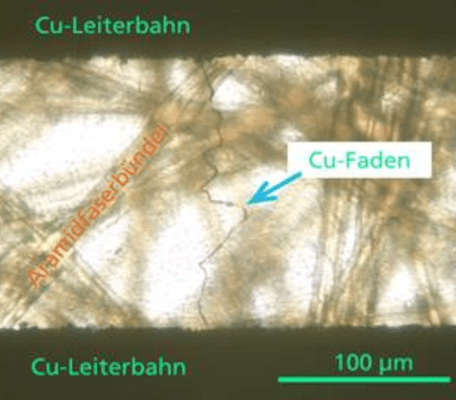

transmitted light image of circuit board

transmitted light images of circuit board

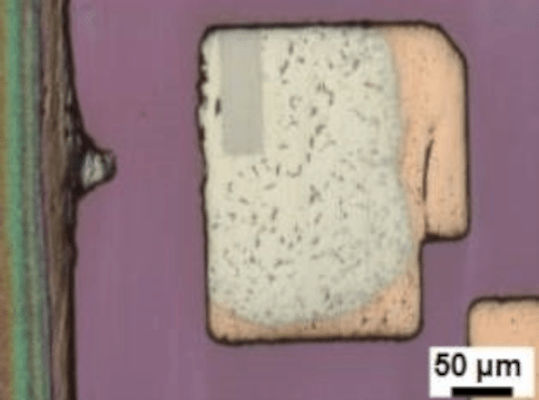

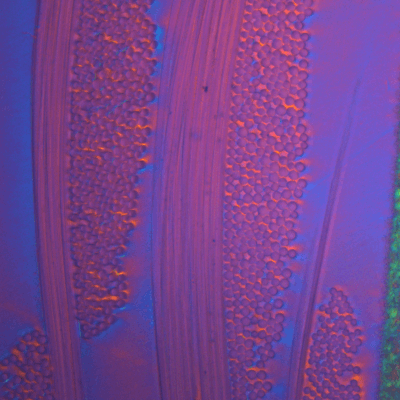

surface cut sintered compound (detail)

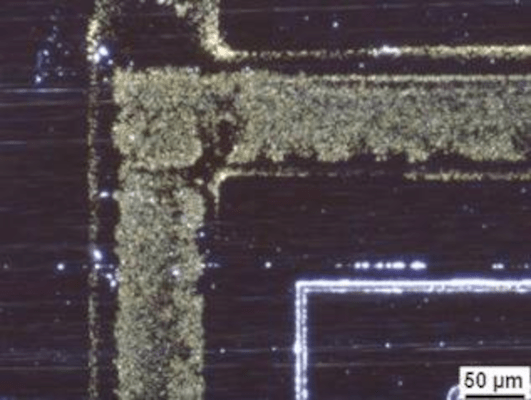

surface cut: bond frame from AuSi (Dunkelfeld)

surface cut detail: bond frame from AuSi (Dunkelfeld)

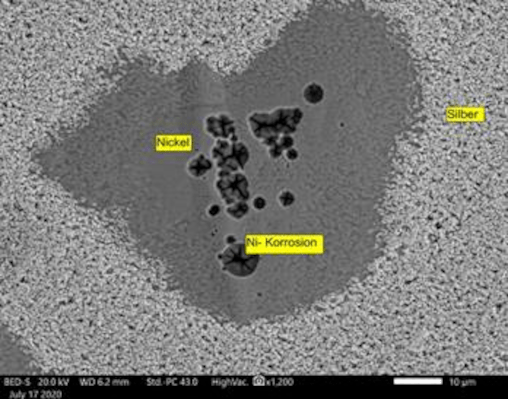

surface cut silver layer with protruding Ni islands with corroded areas

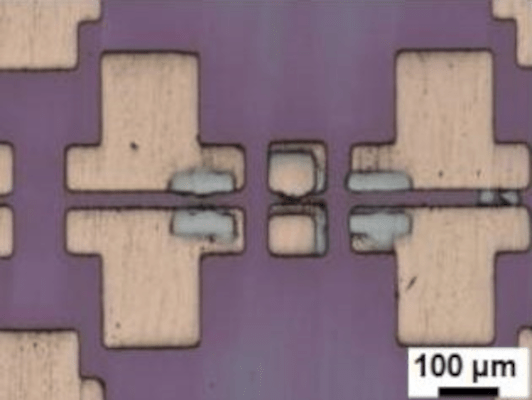

connection zone CuSn

surface cut detail: connection zome from CuSn

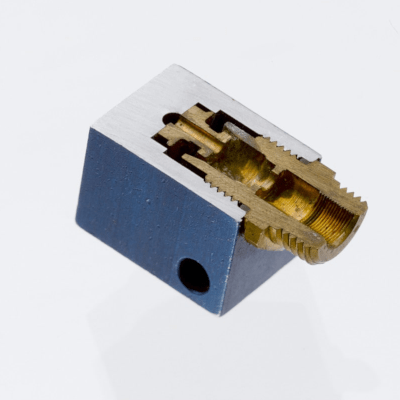

EXAKT thin sectioning technology for industrial applications

Thin sectioning is a two-sided grinding process of a specimen mounted on a glass slide and is the prerequisite for transmitted light microscopy. In the industrial practice of thin section production, manual procedures, or fully automatic machines with parallel processing of several specimens, at the same time are common. The EXAKT system takes a completely different approach and focuses on single sample preparation, the unique quality, and reproducibility of the results. The EXAKT system allows µ-accurate stock removal in the grinding process, achieves exceptional precision in plane parallelism and outstanding surface quality. Furthermore, the special measuring technology allows the processing of specular or highly reflective samples that cannot be processed with laser measuring systems.

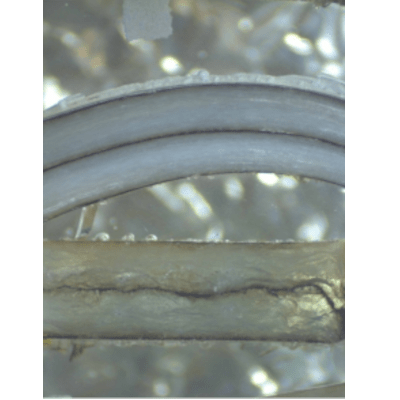

thin section composite

thin section composite