Das µm entscheidet

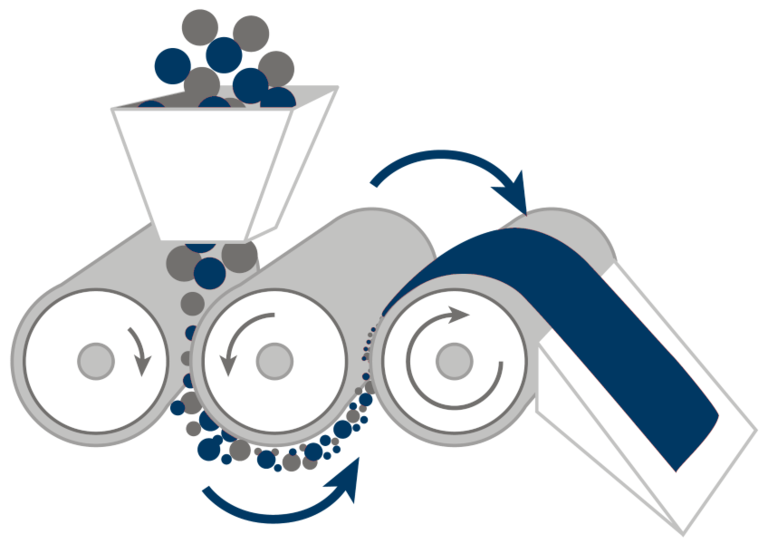

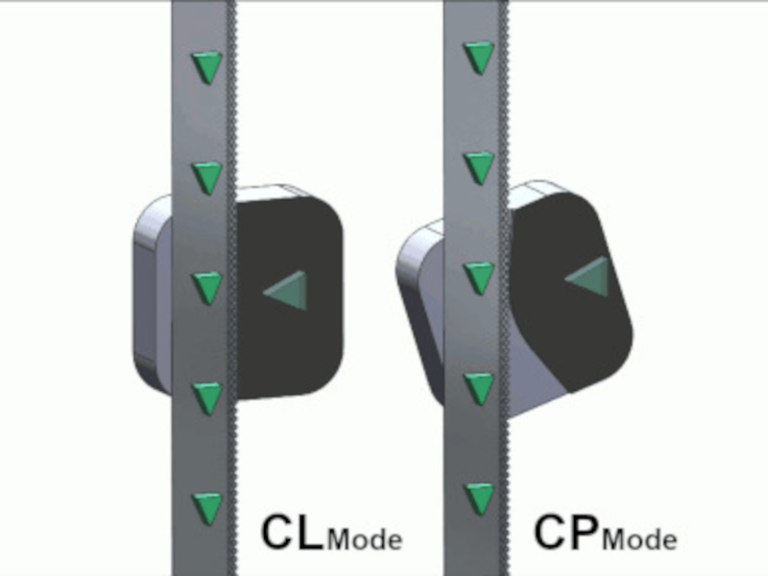

Dreiwalzwerke

Die effektivste Art, Materialien zu benetzen, homogenisieren & zu dispergieren.

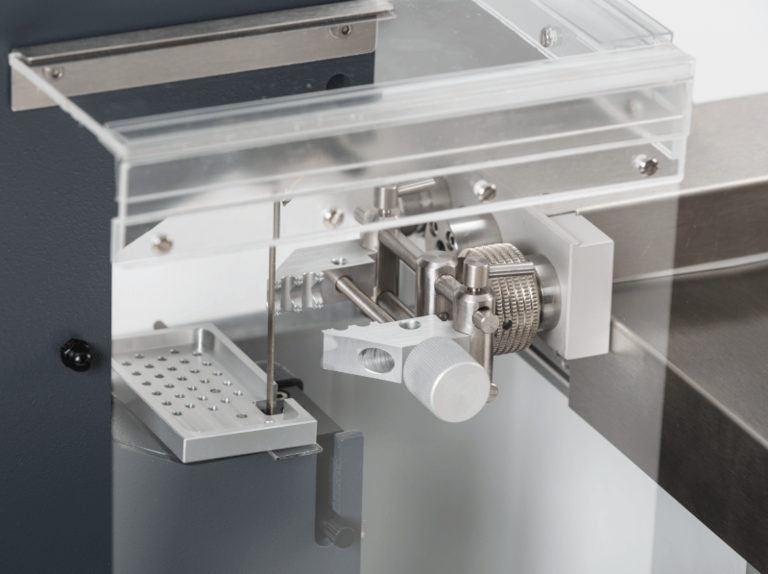

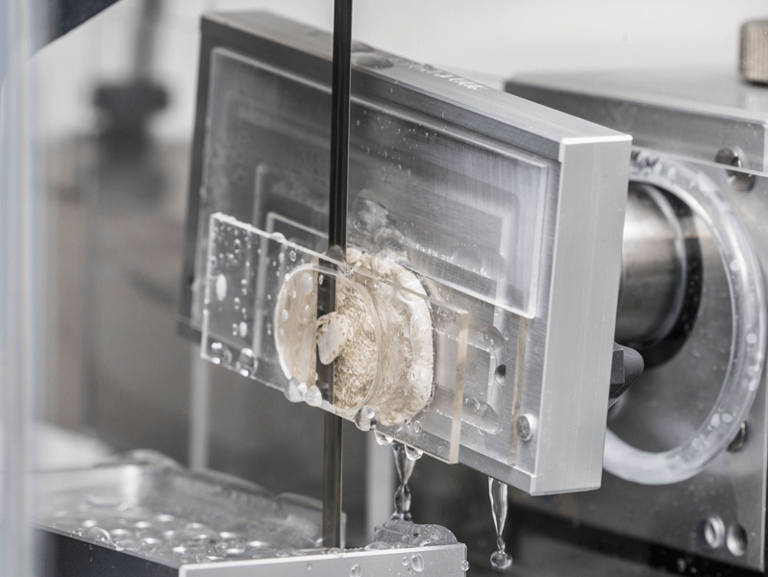

Trennen & Schleifen

Die effizienteste Art der Probenpräparation verschiedenster Materialien und Materialverbunde.

Bei EXAKT stehen wir für absolute Präzision, Leidenschaft für Technik und einen immerwährenden Fokus auf Innovation. In unseren Werken in Norderstedt bei Hamburg produzieren wir hochpräzise Dreiwalzwerke, Salbenmühlen, sowie Trenn- und Schleifsysteme "made in Germany".

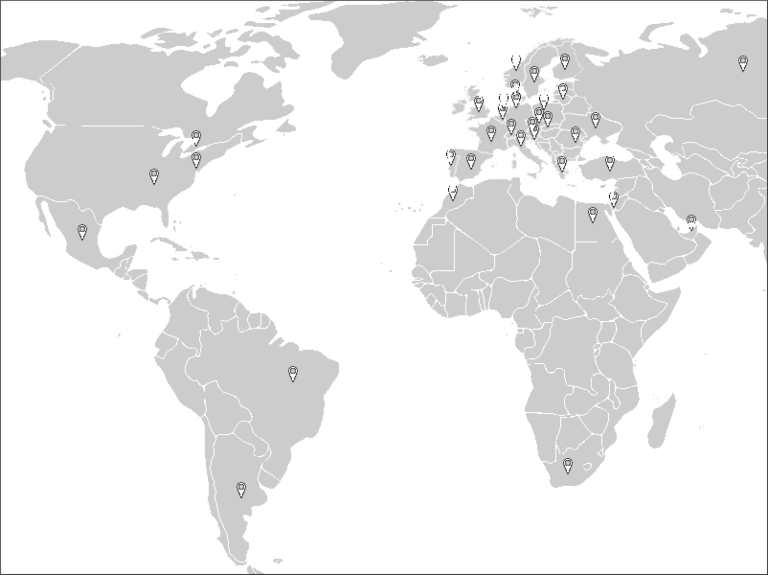

Seit über 70 Jahren werden unsere Produkte und Technologien in den unterschiedlichsten Branchen und Anwendungsgebieten eingesetzt. Wir bieten die passende Lösung für jedes Arbeitsumfeld, ob für Anwendungen im Labor und der Entwicklung, der universitären Forschung oder in der industriellen Produktion, EXAKT steht weltweit für zuverlässige Präzision in Perfektion.

Kontinuierlich optimieren wir unsere Maschinen und Systeme, um den zukünftigen Anforderungen unserer Kunden entsprechen zu können. Unsere Kunden finden nahezu überall und jederzeit kompetente Beratung und Service durch unsere internationalen Fachhändler oder direkt durch EXAKT.